Manufactured Home Setup Material Buyers’ Guide

The following buyers' guide will help you in finding the best product for your needs.

Determining What Size ABS Pad Or Footing To Use

How To Determine Soil Density Using A Penetrometer

When installing a manufactured home, it is important to determine the soil density where the footings will be located under the home. This is done by using a soil penetrometer.

Once you have determined the pier load requirements by using the home manufacturer’s setup manual or HUD code 3285, you can now choose the most cost effective footing or PAD to set the home.

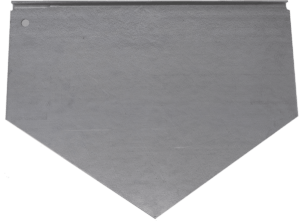

There are many ABS Pads to choose from depending upon the soil and load requirements.

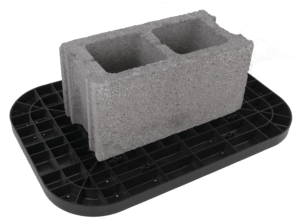

ABS Pads

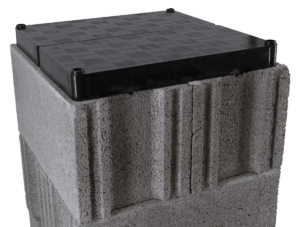

Building The Piers

Once you have determined the proper size pad, you will need to build your piers utilizing either steel piers or concrete blocks. Steel piers are available in several heights and two head options. When using concrete block for piers, you will utilize cap boards and wedges to gain the proper support height.

Steel Piers & Heads

For Pier Loads Up To 6,000 LB

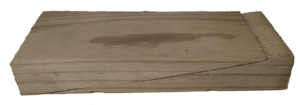

Cap Boards

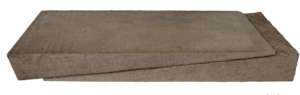

Wedges

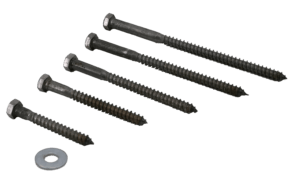

Determining The Proper Anchors To Use

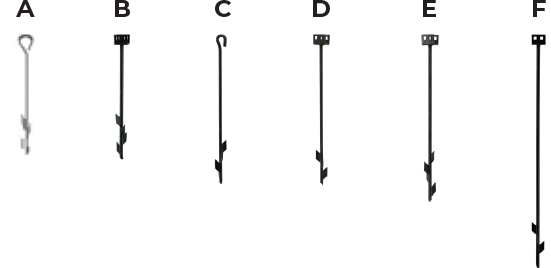

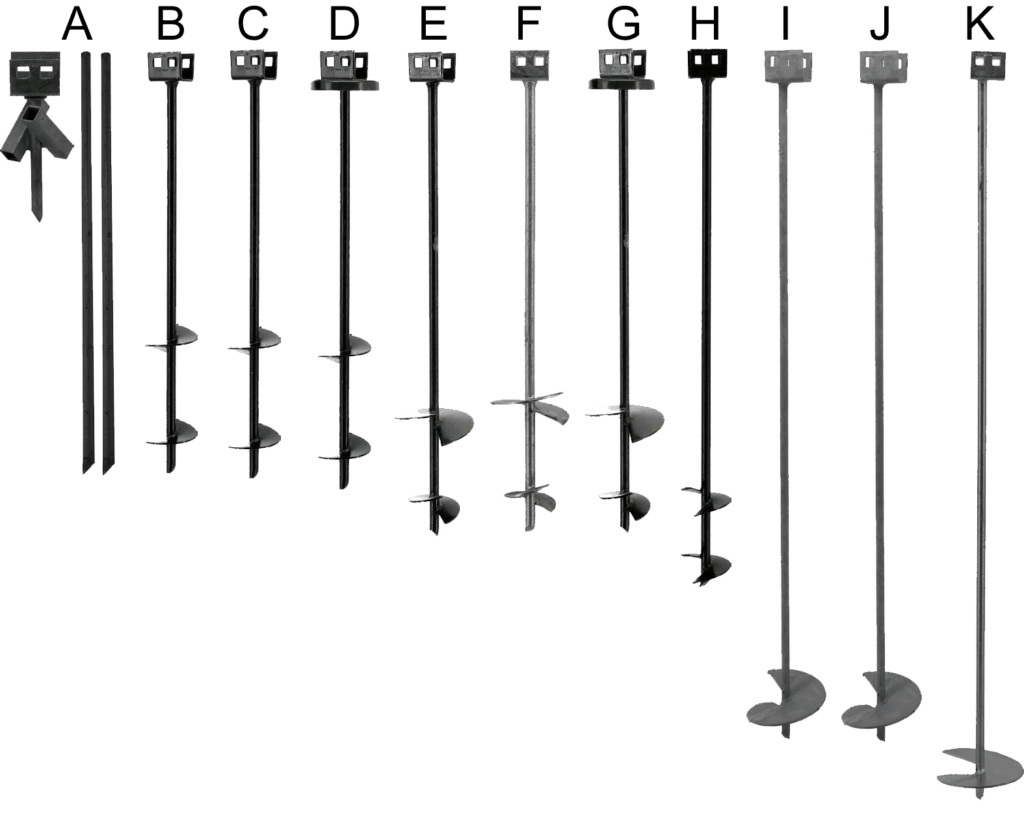

There are a couple of types and several size anchors used when securing down a manufactured home or other building. For dirt installation, you will need to use a torque probe to determine the proper size earth auger anchor needed.

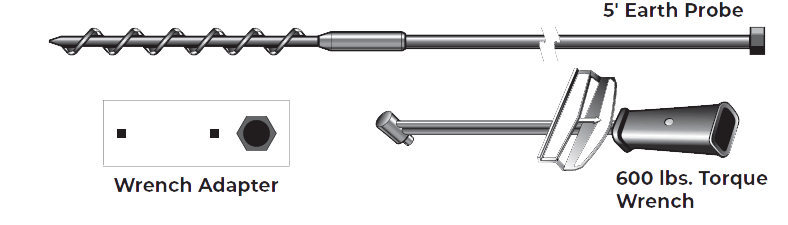

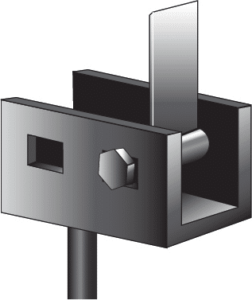

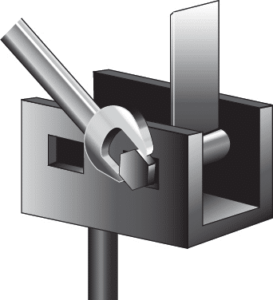

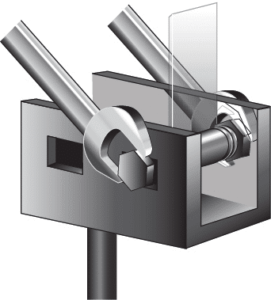

Torque Probe

The Torque Probe is needed to determine the soil classification where the anchor's helix will be located in the ground. Use the Soil Classification Chart on the next page to see recommended anchors for each soil condition. Once you have determined the proper size anchor from your Torque Probe results, refer to the home manufacturer’s setup manual or HUD code 3285 to choose the proper anchor spacing needed.

Torque Probe Instructions

- Place the tip of the earth probe in the ground, closest to where you intend to install the anchor. Rotate the probe clockwise using a 15/16" hex socket or electric drive machine.

- Rotate the probe into the soil until you have reached the depth equal to the length of the anchor you intend to install.

- Place the wrench adapter on the torque wrench and insert the hex portion of the wrench adapter onto the earth probe.

- Steadily rotate the torque wrench on the probe while supporting the probe with the opposite hand. (Do not exceed 600 inch lbs.)

- While rotating clockwise, view the torque wrench test value.

- Use the Soil Classification Chart on the next page to determine the proper anchor needed for the soil conditions.

- If test results do not match the anchor for that depth, rotate the probe to the next anchor depth and check reading. Repeat until probe reading matches anchor length for depth of reading.

Soil Classification Chart

Use the chart below to choose the proper earth auger anchor for each soil classification.

* Contact us about additional sizes that may be available

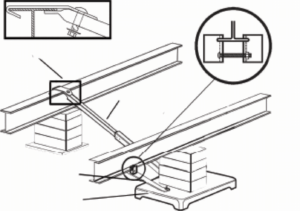

Anchor Stabilization Devices

Stabilizing devices are used when the anchor is connected to the main chassis beam and is pulled at a 45 degree angle or cross strapping.

Stabilizers

Determining The Proper Tie Down Connectors & Straps

When securing a home, there are several areas that need to be tied down to make the home safe. Now that you have chosen the proper anchors and stabilizing devices, you will need to determine the attachment connectors on the frame or side wall, as well as longitudinal protection and the proper strap lengths. We have several options for you to choose from.

Tie Down Connectors

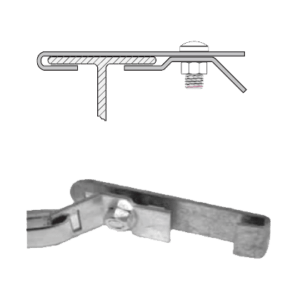

Longitudinal Connectors

When homes are equipped with pre-installed sidewall and/or longitudinal brackets, you have a couple of choices.

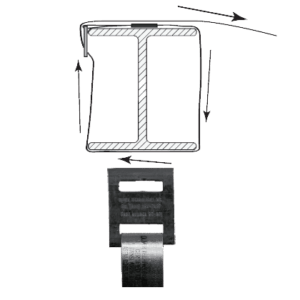

Longitudinal I-Beam Connectors

Part # OTLTK

* Quick Connector Sold Separately

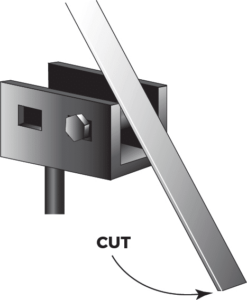

Step 1

Insert split bolt into anchor head, attach loosely. Pull strap past bolt and cut strap leaving approximately 12“ of strap to wrap onto bolt.

Step 2

Insert the strap end into the slot in bolt until flush with opposite side of bolt.

Step 3

Using 15/16” wrench or socket; turn the bolt, winding the strap so that a minimum of four to five complete turns are made and the strap is adequately tensioned so that the anchor is firmly against the stabilizing device in direction of pull.

All slack must be removed.

Step 4

Hold the bolt under tension while tightening the nut, drawing the head of the bolt into the recess, continue to tighten the nut until securely fastened.

Foundation Stabilization Systems

An innovative alternative to conventional anchors is our All Steel Foundation Systems (ASFS). These systems eliminate the need for most anchors in Wind Zone 1. In Wind Zones 2 & 3, ASFS eliminates the need for diagonal frame ties, stabilizer plates and anchors required for longitudinal protection. ASFS can be used in all soil classes up to 4B. All Steel Foundation Systems are available with or without a pier support.

All Steel Foundation Systems With Pier Support

Supporting The Perimeter Of The Home Or Building

There are several door/window and perimeter pier support options. Typically perimeter supports utilize footing that are installed at or below frost depth. Oliver Technologies offers a few alternative perimeter support options that are not affected by frost heave, making your perimeter support installations fast and easy.

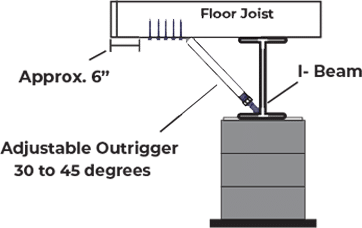

Adjustable Outriggers

The Adjustable Outrigger has been designed to replace perimeter piers with a maximum working load of 1740 lbs. Refer to the installation manual or home manufacturer for roof loads, pier loads and location of perimeter piers.

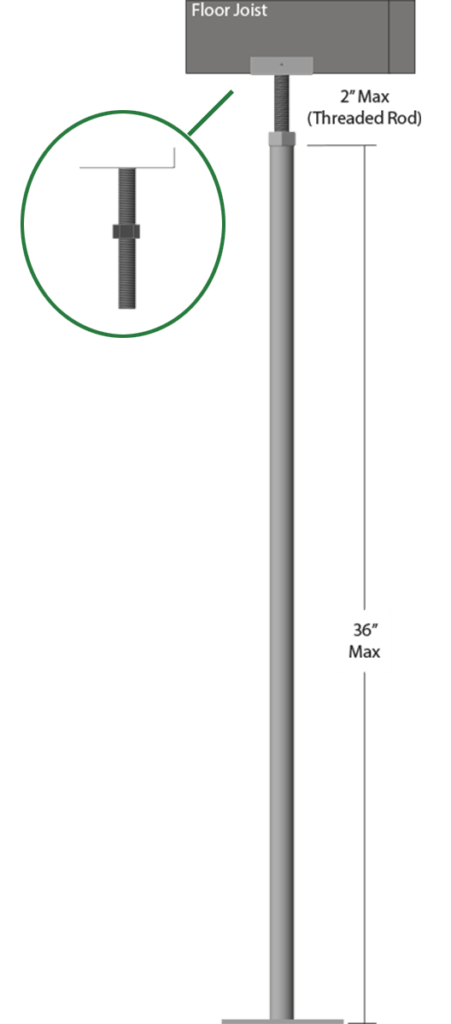

EZ Piers

The EZ Pier is another replacement for the conventional perimeter support. It can be used for pier heights up to 39" and features a 2" adjustment. The pipe can be cut-to-fit for shorter heights. It has a maximum working load of 4,000 lbs.

Sideline Support

Part # OTIS3

This perimeter pier option is used for difficult soils with a maximum pier load of 4,800 lbs. and can be used with perimeter pier heights up to 60". It can also take the place of two perimeter piers for openings up to 48".

- 2” of adjustment, cut to fit

- Eliminates one base pad/footing

Choosing The Right Steps

Fixed Wood / Metal Steps

Our Wood/Metal Steps feature painted black metal frames and treated treads. They are available in several heights, platform depths and your choice of Standard or IRC compliant steel handrails.

Get All Decked Out

ProLine Decks: Available in 4-Module, 6-Module, 9-Module Deck Kits

Our patent pending modular design allows you to quickly build a deck in hours versus days. Simply find the slope,order the deck kit and put it together in no time flat.

Other Products You Need To Complete The Job

Multi-Purpose Anchors

If you need anchors for swing sets, trampolines, trees, carports and more, choose from the anchors below.